AUTOMOTIVE

mehr erfahren ›

Was im schönen Lerbach, einem Stadtteil von Osterode im Jahr 1932 seinen Anfang fand, ist nun zu einem international agierenden Unternehmen mit breiter Ausrichtung geworden. Die KKT Gruppe bietet Ihnen eine weitreichende Palette an vielseitigen Produkten, von der Entwicklung und Produktion bis hin zur Komplettierung und Belieferung. Zu unseren Kunden gehören neben der Automobilindustrie namhafte Konzerne aus allen Bereichen der Wirtschaft.

Innovative Verarbeitungs- und Bearbeitungsverfahren, darunter auch automatisches Lackieren, Handlingsautomaten und Mehrkomponentenfertigung, sowie unsere globale Ausrichtung ermöglichen es uns, die Ansprüche unserer Kunden optimal abzudecken.

Zu den Schwerpunkten der KKT Frölich Kautschuk-Kunststoff-Technik GmbH gehört die Herstellung von Gummi- und Silikonteilen. Dieses beinhaltet auch die direkte Mitentwicklung in der Entstehungsphase des Endproduktes. Die Konstruktion der Fertigungswerkzeuge stimmen wir mit unseren Kunden und ausgewählten und spezialisierten... weiter lesen ›

Die Firma Norsystec Nohra-System-Technik GmbH mit Sitz in Bleicherode, wurde im Jahr 2008 als eine 100% Tochterunternehmung der KKT Holding GmbH gegründet.

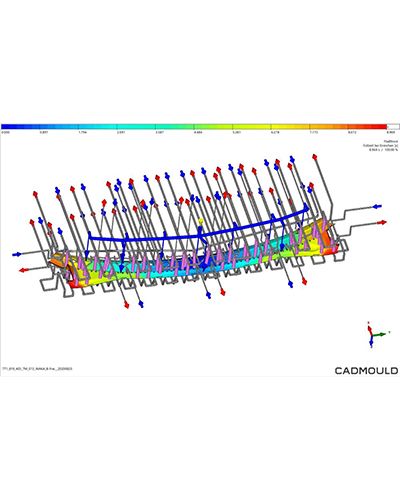

Auf modernen Spritzgießmaschinen werden Kunststoffteile für die Automobilindustrie hergestellt. Nachgelagerte Montageprozesse werden direkt an und durch die Maschinen erledigt, bzw. werden in der eigenen Montageabteilung zu komplexen Baugruppen zusammengefügt... weiter lesen ›

1971 als kleiner Werkzeugbau mit 5 Mitarbeitern im oberfränkischen Pressig gegründet. Ende der 70er Jahre ergänzt um den Kunststoffspritzguss mit der Spezialisierung auf Steckverbinder und Mehrkomponententeile. In mehreren Baustufen wurde der Standort erweitert und umfasst heute 30 Spritzgussmaschinen mit Zuhaltekräften von 25 bis 200 Tonnen und einen voll ausgestatteten... weiter lesen ›

Gemeinsam Zukunft gestalten

Sie suchen ein Unternehmen das Ihnen mehr bietet?

Mit der KKT-Gruppe haben Sie eines gefunden. Als einer der Marktführer im Bereich der Kautschuk, Kunststoff und Silikon verarbeitenden Industrie bieten wir vielfältige berufliche Perspektiven für engagierte, ambitionierte und weltoffene Menschen. Wenn Sie mit Begeisterung und Leidenschaft ihre Ziele verfolgen und wie wir höchste Ansprüche an sich stellen, dann finden Sie bei uns genau das Umfeld, in dem Sie Ihre Talente voll entfalten können... weiter lesen ›

Weiterlesen … Norsystec beschäftigt mit die beste Auszubildende

Weiterlesen … MdB Dr. Jonas Geissler zu Gast bei KKT Pressig